MONOSCOPE TUBE

|

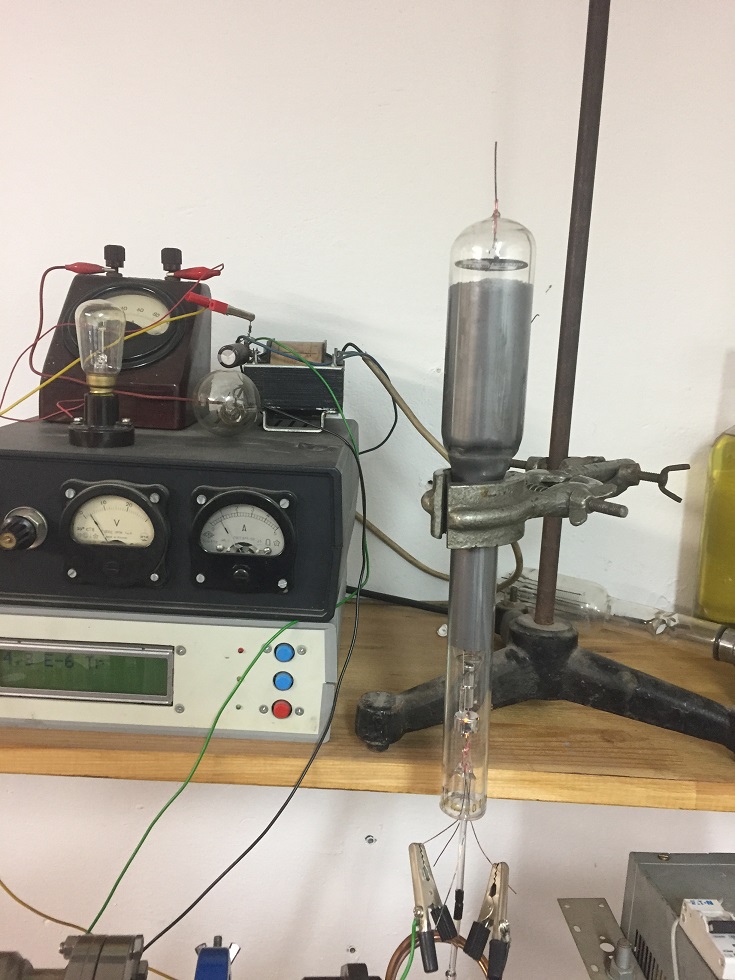

This will be a description of the construction and a test report of my M2 monoscope operation.

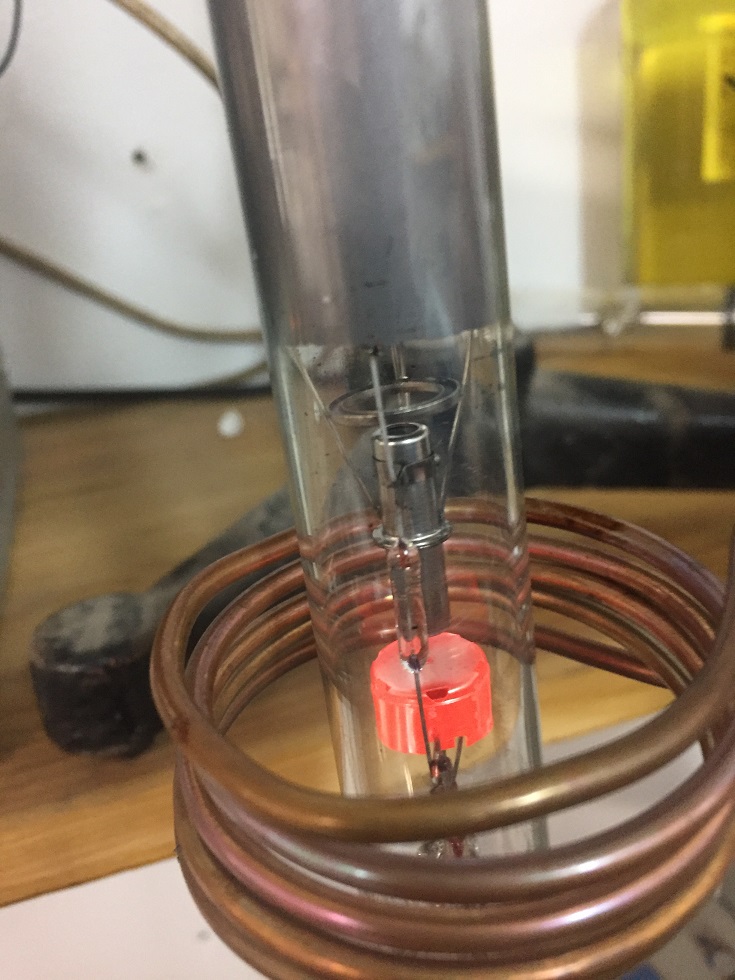

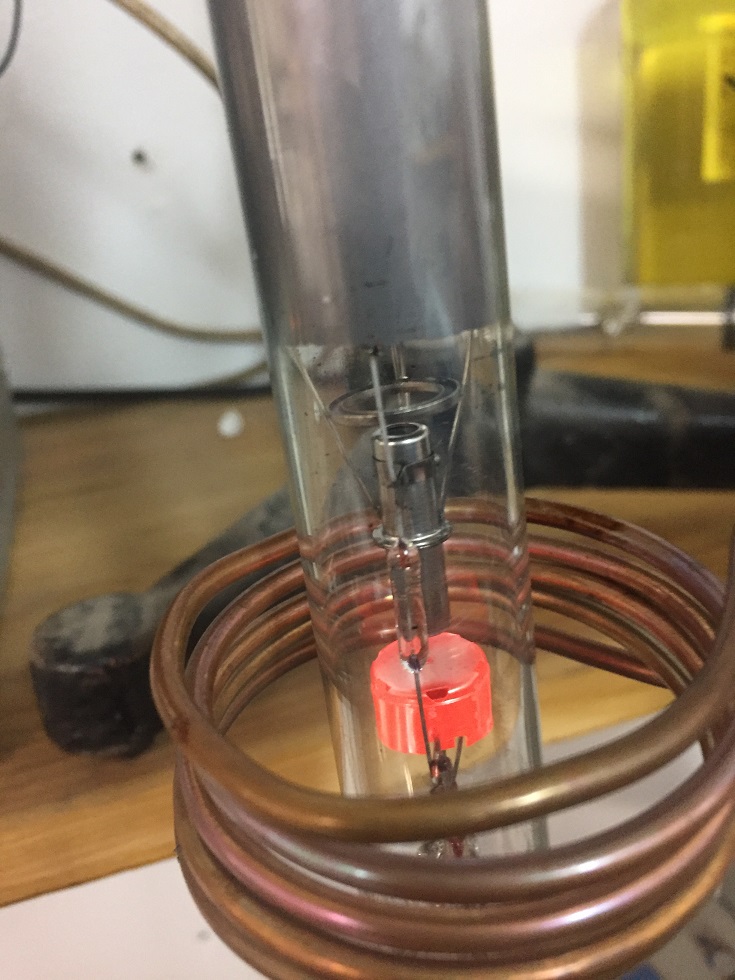

This is a small demonstration monoscope with magnetic focusing and deflection.

It was equipped with a simple test pattern containing two words "Replika", two light rectangles and two dark circles.

Parameters of the M-2 (PWL) monoscope:

- Filament voltage: 2.1V

- heating current approx. 0.7A

- Oxide cathode, indirect heated

- Collector voltage 1750V (1300-2500)

- Signal current approx. 1-5 microamps

Image on target:

|

The method of making a black and white target without signal gray gradation is as follows:

The signal plate can be made of aluminum sheet. In order to cut out the appropriate tiles.

I used sheet metal with a cleanliness of "pure for analysis" and a thickness of 0.5 mm. The plate should be etched in a 10-20% warm sodium hydroxide

solution "pure for analysis". Digestion time 1- 3 minutes. Then the plate should be thoroughly rinsed with distilled water and dried.

Then you need to put the drawing template to be on the monoscope board on the plate.

The template is nothing more than a thin sheet of metal with a drawing etched through it.

The template is best pressed with tweezers so that it adheres to the aluminum disc.

Failure to do so will make the image out of focus, blurry. The unsuccessful drawing

can be removed by washing with water and detergent and re-etching the tile.

Then soot the monoscope plate through the template. It's best to get soot at the top of the flame.

There, the soot is released, and not the greasy stearin, which is harmful when the plate is mounted

in the tube. Make sure that the tile is evenly covered with soot in exposed areas.

It's good to have a welded metal "whisker" for the template. After smoking, carefully put the signal plate face up.

Then, with tweezers, carefully pick up the "whisker" template so as not to wipe the image off.

Then it is advisable to look at the plate in a "dismountable monoscope". In my case, the plate could be viewed in an electron beam welder.

You can then assess the contrast of the image, etc. Accelerating voltage 1.5–2.5 kV. Beam current 0.1-0.2 mA

(approx. 10 cm from the collector of secondary electrons in electron beam welder). It is also advisable to act

on a 5-6 mA / 3-4 kV beam in order to heat it under vacuum (10^-4 Torr).

|

Then, the bracket and the plate outlet are heated to the signal plate and mounted in the tube

(its wider part). The inner part is covered with an aquadag, leaving approx. 0.5 cm in

front of the target and approx. 1 cm from the open end of the pipe. Then the narrow part of the

balloon is joined - the neck. After joining, the part in the middle is covered

with the aquadag and its connection to the wider part of the glass shield.

From the end of the open end of the glass shield a certain piece is left clean,

such as the "whiskers" of the anode of the electron gun touching the aquadag.

After drying, the aquadag is baked at 300 degrees in an oven for approx. 1-2 hours

and allowed to cool.

An electron gun is prepared separately.

Wehnelt-cathode distance approx. 0.5 mm. Wehnelt-anode distance approx. 4 mm.

Electron gun is mounted in the tube.

The next step is pumping below 5x10^-6 Torr, heating tube and electrode in order to outgasing, forming cathode and flashing getter.

After disconnecting from pump, electrical connectors are added.

|

|

|

|

The monoscope tube is ready to work.

|

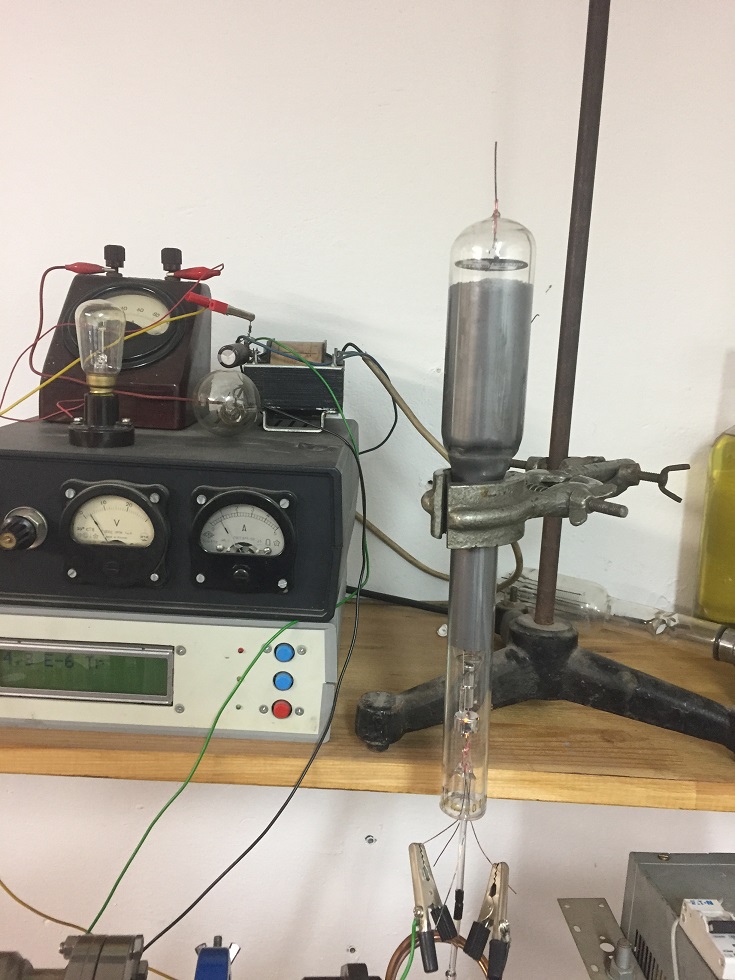

The voltages are given: focusing current approx. 0.3A, deflection signals,

filament voltage 2.1V, Wehnelt voltage 0V, accelerating voltage 1750V.

The beam current under these conditions should reach 50-60 microamperes or even more.

By adjusting the focus current and deflection signals, one should obtain an image with the correct proportions.

Proper contrast can be achieved by reducing the monoscope beam current (at approx. -9V at the Wehnelt electrode,

the beam current is approx. 10 microamperes).

A spiral deflection of approx. 30 "turns" and a refresh rate of approx. 15 Hz was used.

The useful signal from the monoscope with a beam current of 100 microamapers at an accelerating voltage of 2200V,

on a 12 kohm resistor had an amplitude of about 60 mV. This means that the signal current is not less than 5 microamperes.

With a voltage of 1500V, this signal can be estimated at approx. 1 microampere, with a beam current of 20 microamperes

(Wehnelt electrode voltage approx. -5V). Accelerating voltage range 1300-2500V. 1500-1800V is recommended.

|

|

Back to main page

Back to TV Retro page